NOVAXIL™ Silica Flyeye Lenses

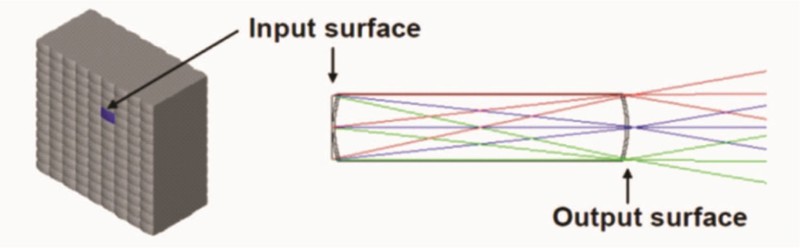

Flyeye Lens, or Lens Array, is an array collection of a pair of lenses with overlapping optical axes. The light focused by the first lens is concentrated on the second lens, and the principle of multiple superposition of light to achieve the function of uniform light.

The flyeye lens is often used in the projection system of the DLP platform, and it provides an uniform illuminating light source for the DMD panel after collocating with the condenser lens. The flyeye lens has the advantage of being small in size, and is very suitable for micro projectors and 3D printers with limited mechanical size. The flyeye lens is potentially to be used in automotive head-up-display (HUD) for better convenient living experience.

Schematic diagram of the working principle of the flyeye lens

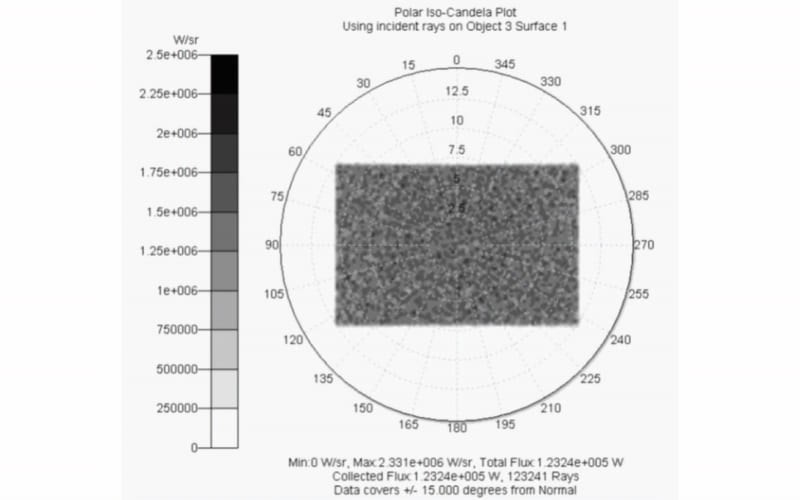

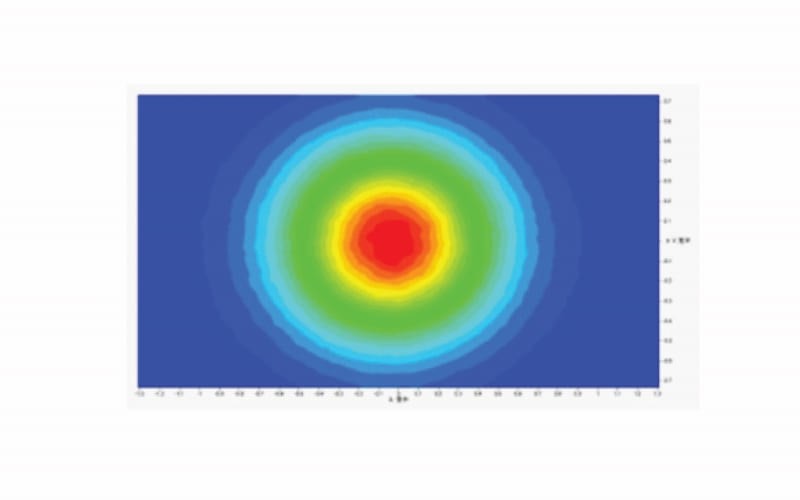

Simulation diagram of the light spot of the light source passing through the flyeye lens

NOVAXIL™ Flyeye Lens Features

- High purity silica glass

- One-piece double-sided molding

- Precise alignment of the optical axis

- Microstructured array

- Minimize dead space

- Competitive price

- ISO certified production process

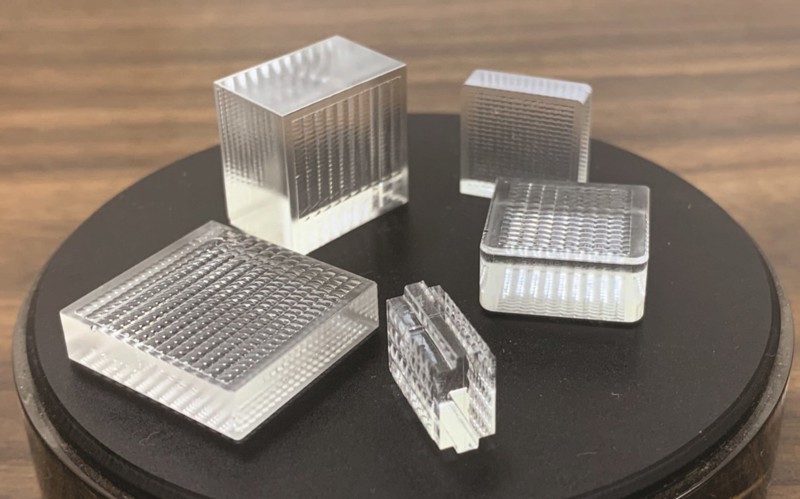

One-piece double-sided molded microstructure flyeye lens

Due to the high threshold of manufacturing process required for flyeye lenses, the industry generally uses two single-sided flyeyes to align with each other as the mainstream for mass production. Cristal Materials provides a solution to such an issue with NOVAXIL™ double-sided silica flyeye lenses.

NOVAXIL™ silica flyeye lenses with one-piece double-sided molded structure

The unique nano sol-gel process of Cristal Materials realizes the double-sided molding of NOVAXIL™ silica flyeye lenses, which are extremely small cell units and minimized dead zone areas under the premise of integral molding of components. Integration of hundreds or even thousands of microstructured cells in a small area provides a solution for high-lumen projector with minimized efficiency loss.

Real shot of NOVAXIL™ flyeye lens for surface conditions

Laser microstructure flyeye

In the fast developing laser light source system in recent years, the fluorescent wheel cannot withstand the high intensity energy of the blue light laser, which is usually failed by reliability problems. At this time, the tiny structure of the diffuser is often used to disperse the laser spot.

Simulation of the spot of the laser light source passing through the diffuser

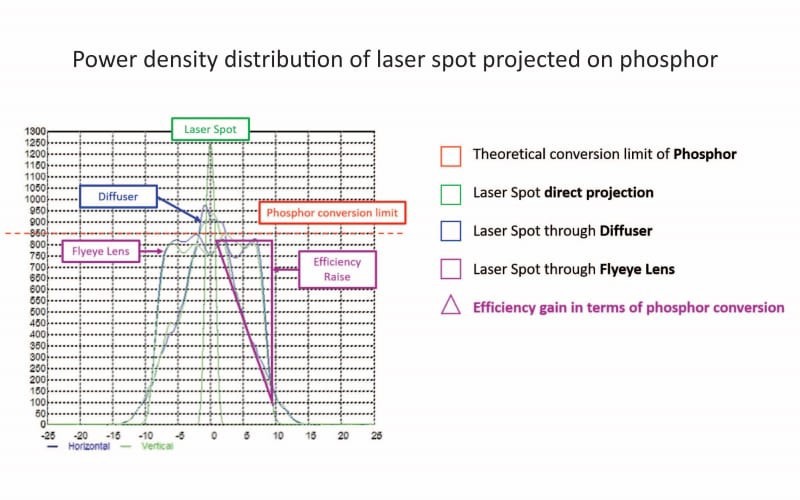

However, the optical characteristics of the diffuser are Gaussian distribution, and the diffused light spot is circular, and the energy conversion rate and energy utilization rate are not as good as that of the Micro Lens Array. Therefore, trends in the development of high lumen projectors are moving toward microlens array designs.

Simulation of the spot of the laser light source passing through the flyeye lens

From the structural simulation analysis of the laser light source projected on the phosphor wheel, microstructured flyeye lenses can effectively bring down the power density of the expanded beam spot. The flyeye lenses improve the uniformity of the energy distribution, and reduce the thermal decay of the phosphor particles. Enhanced phosphor conversion rate benefits as a positive result because of lower power density on the phosphor. In addition, the rectangular light spot shaped by the flyeye structure improves even further the energy utilization efficiency, and significantly improve the brightness performance of the light source system.

Comparison of power distribution while laser light source penetrates different structural surfaces

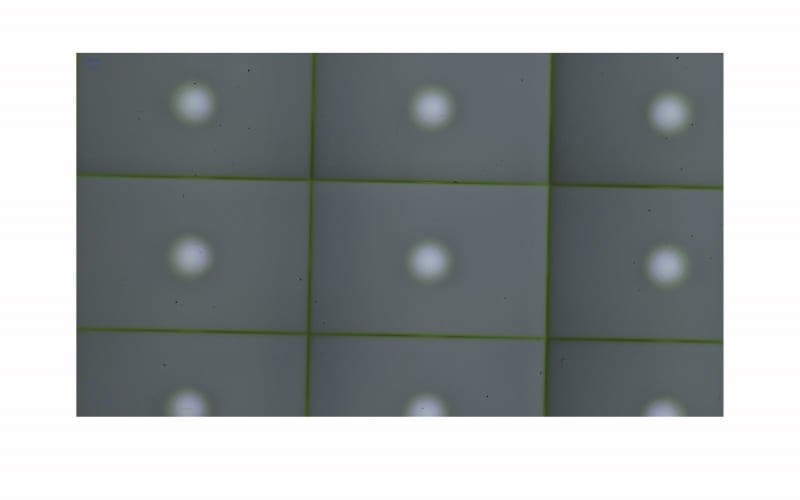

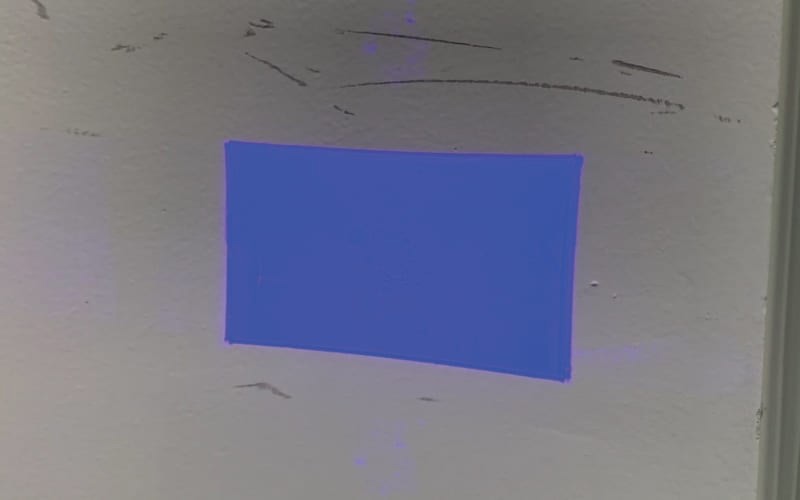

NOVAXIL™ microlens array flyeye could reach 0.3 mm cell size with minimized dead zone width not exceeding 0.03 mm. So that the laser light source can expand and homogenize the beam , and at the same time organize the light spot into a rectangular light type commonly used in projection systems . NOVAXIL™ is a high purity silica material that does not absorb any visible spectrum, and withstand high intensity laser light sources, especially suitable for high brightness laser projectors (above 2,000 lumens).

NOVAXIL™ microlens array actual projection spot

NOVAXIL™ microlens array actual projection spot

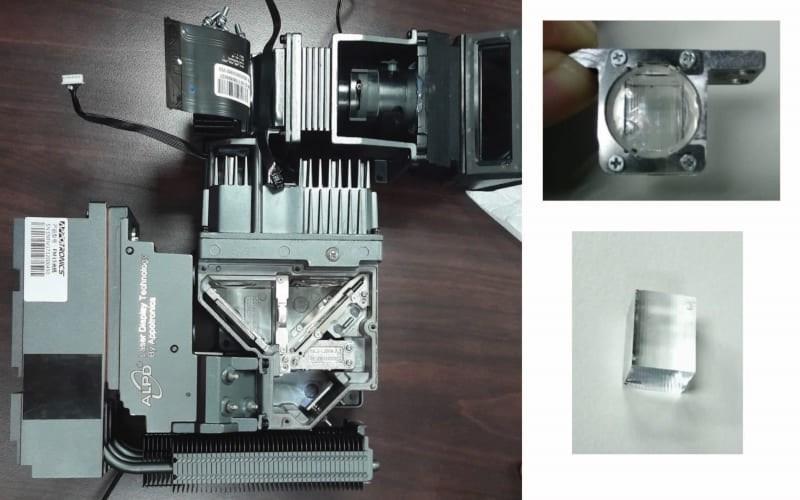

Engineering achievement

Regardless of your light source type or application wavelength, NOVAXIL™'s broad spectral coverage and material durability ensure long-lasting light quality for any type of projection system. NOVAXIL™ flyeye lenses have been designated by well-known laser projection manufacturers for years. Recently, NOVAXIL™ flyeye series also provide UV-durable solutions for 3D printing customers.

With the excellent technical features of NOVAXIL™ flyeye lens, we help customers to improve the overall brightness of the projector and the durability of the light source. With proactive investment in R&D of our core technologies, our goal is to meet customers' needs for light, and continue to explore the infinite possibilities of projection technology.

Engineering achievement of NOVAXIL™ laser microstructure flyeye lens

Laser Projector with NOVAXIL™ microstructured flyeye lenses

Laser Projector with NOVAXIL™ microstructured flyeye lenses (real scene)

Laser Projector with NOVAXIL™ microstructured flyeye lenses (real scene)

Projector customers using NOVAXIL™ flyeye series

For the design parameters and capability range of NOVAXIL™ flyeye lens, please refer to the technical specification link

< Extended Technology : NOVAXIL™ Flyeye Lens Specifications >